Designed for the handling of glass and mineral filled Plastics, and other abrasive powders and granules, NiTec elbows, valves and manifolds outlast ceramic, chrome plated and Titanium Alloy parts.

NiTec, Abrasion Resistant Pneumatic Conveying Elbows and components use a proprietary “NDS” (Nitrogen Diffusion System) process that raises the abrasion resistance of Stainless Steel from a normal level of 145 to 1400 HV on the Vickers scale, making the NiTec treated components 3x harder than Titanium Alloy and 50% harder than Ceramic coatings. The NDS treatment is not a coating that can chip off and contaminate molds and all NiTec Elbows use normal Bolted Couplings making installation simple and fast.

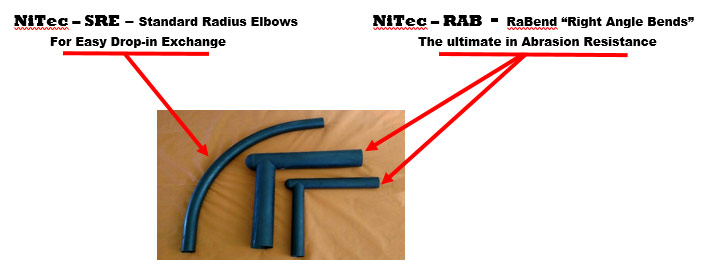

NiTec Pneumatic Conveying Elbows

- NiTec – SRE: Standard Radius Elbows for medium to heavy abrasion problems. Available in any radius for easy “drop-in” replacement.

- NiTec – RAB: “RaBend” design for the ultimate abrasion resistance.

NiTec Pneumatic Conveying Elbows because:

- SRE and RAB are priced at less than 50% of cast alloy elbows

- No angle hair – No fines

- Superior abrasion resistance

- SRE – available in all radius options for easy drop-in replacement

- Corrosion resistant

- Smooth internal and external surfaces

- Easy to install – Standard tube gauges and radius in SRE models

- No special supports needed

- Outlives ceramic and chrome-plated parts

- No chipping off of ceramic or porcelain that can damage molds

- Elbows and fittings use conventional Morris couplings

- No special flanges – adapters are available for connections

NiTec Pneumatic Conveying Elbow Options